When working with wood and creating woodworking projects it is essential that you use some type of joint to attach pieces of wood in order to create a finished piece.

It can get confusing and overwhelming rather quickly if you are new to woodworking as there are quite a few types of joints and each of them has their own weird names.

Different Types Woodworking Joints

People search about how to make wood joints by hand, or tools inside a home can look at the points given below.

1. Butt Joint: Easy and Simple

Butt joints are easy and the simplest joints to make while also being the weakest. This joint joins two pieces of wood by basically butting them together. It requires some reinforcement if it is going to see any pressure on it as they are very weak on its own.

You basically glue the pieces together and because you are gluing end grain to the long grain of a piece of wood the joint is very weak. Gluing wood is also not a very strong and smart idea as there is not much lateral strength. This can be used on simpler projects which are merely for decoration.

2. Biscuit Joint for Mortise and More

A biscuit joint is going to be a butt joint but just reinforced. The biscuit is oval in shape and is usually made of dried and compressed wood. Beechwood is usually seen to be used for the biscuits. It has to be installed in matching mortises in the mating surfaces of the pieces of wood.

A biscuit joiner is recommended to make the mortises but it does not have to be precise. The biscuit joint is made to have more room to correct when gluing the surfaces together. You must find the correct distance from the surface of the joints to the mortise in both pieces of wood.

This is because the width of the mortise is not critical and due to the biscuit being quite thin, you are unable to perfectly align the pieces. This is why this joint is not preferred by many and it also requires a lot of time in cutting mortises.

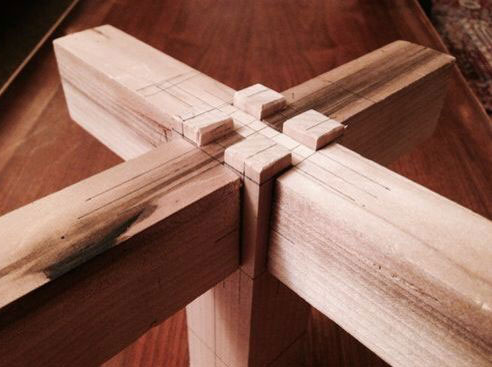

3. Bridge Joint: A Precise Joint for Legs

Bridle joints are somewhat similar to mortise and tenon joints. To make this joint, you need to cut a tenon on one end of the wood and a mortise on the other to place them together like a piece of the puzzle.

The mortise and the tenon are cut to the exact width of the piece you are cutting the tenon on. This means that there are only three surfaces that require to be glued together. This joint is used in creating legs of a table or anything that you need to stay standing.

It can handle quite a lot of pressure and is reasonably resistant to racking. To finish the joint, a pin or any other mechanical fastener is needed and the joint can be taken apart even after everything is put together without damaging it.

There is also another bridle joint called the T-bridle which basically joins the middle of one piece to the end of another which works just as well.

4. Dovetail Wood Joint for Strong Woodworking

These joints are simply called dovetail and are a strong joint that is used quite frequently in woodworking projects. The dovetail joint is great for any joint that is going to face a pulling force as it is resistant from pulling apart.

It can be used to attach sides of a drawer to the front of it by extending a series of pins along with the whole piece of the wood and the other piece of wood has a series of tails cut in it.

Once the two ends are glued and put together, a permanent strong joint is formed without the need for any mechanical fasteners. Some people even make dovetailed dados because they are even stronger and more resistant from pulling apart.

5. Dado and Rabbet Joint

Dado is a slot that is cut in the wood. A dado has three sides and has to be cut perpendicular to the direction of the grain. You might think it is like a groove but a groove is cut parallel to the grain unlike a dado. The dado is cut along the whole surface as needed.

A rabbet is made on the mating surface and is a step-shaped recessed cut to accept the dado. These can be used to attach shelves to a cabinet or any other places where you can think of creating a rabbet on the mating surface and dado on the other to join them. This will then be called a rabbet and dado joint.

6. Box Joint for Joining Two Woods 90 Deegreess to Each Other

Box joints, also known as finger joints are very popular in the woodworking community. These are used to join two pieces of wood at 90 degrees to each other.

It is similar to a dovetail joint but the pins here are square in shape and not angled like in dovetails. The joint is held together with glue and it is not as strong as a dovetail.

This joint is made with a table saw or router relatively easily compared to a dovetail.

7. Mortise and Tenon Woodworking Joints

This is one of the strongest joints in woodworking and is rather simple. It has been used for many years and is still being used. These are used to join pieces to make a right angle.

A mortise is basically a hole and tenon is the projection, taller than it is wide cut on the wood that is to be inserted into a mortise.

8. Half Lap Joint: A Thick Joint for Woodworking

The half-lap joint is frequently used in woodworking. In this type of joint, you need to cut from both pieces which means the resulting joint is as thick as the thickest piece.

A half lap joint is one of the frequently used woodworking joints. You are to remove half of the thickness of each piece and then push both the pieces of wood together like a puzzle piece.

9. Pocket-hole Joinery / Pocket-screw Joinery

This is also another one of the commonly used joints. This pocket-hole joint is basically a butt joint with pocket hole screws. The pocket holes have to made by drilling two holes. At first, you must counter-bore the hole and then you have to drill a pilot hole.

The centerline of the pilot hole is to be the same as the pocket hole. The pilot hole is created to allow the screw to be driven in through one piece and into the other one which needs to be joined.

To do this you must use two different sized drill bits or you can use the stepped drill bits which are specially made for these types of applications but those are not available in all shops.

It is common to see people using a Kreg jig as a pocket hole jig to ensure the pocket holes are drilled at the exact angle required and also to the exact depth.

These jigs cost about $40 to $140 which can be expensive for some people as a mortise and tenon jig can be made for a very small portion of that price. It is recommended that glue must be used to add extra strength to this joint.

10. Rabbet Woodworking Joint

A rabbet is made by making a recessed cut into one of the edges of the wood. It is one of the popular types of woodworking joints people use to improve their home.

If you are to take the piece and view it in its cross-section, you will be able to see a rabbet that is open to the end of the surface and two-sided.

A rabbet is commonly seen to be used in cabinets, more specifically the backside of the cabinet where the edge sits against the wall as the back can sit flush with all the sides. It can also be used when inserting a pane of glass into a frame. That frame can have a rabbet as it needs to sit flush.

11. Tongue and Groove Woodworking Joints

The tongue and groove joint is also known as the edge-to-edge joint. This is made by creating a groove or slot along one of the sides. The other piece will have an edge coming out of it like a tongue that fits into the groove created before on the other piece.

This joint is used when making something very wide such as wood floors, tabletops out of wood, paneling and a lot of other applications. There are multiple different ways of cutting a tongue and grove and it can also be easier and have a better result if you use a router table when cutting.

Final Thought

There are a lot of different types of wood joints, all of which are intended for different purposes with varying pressure withstanding characteristics. In a few tests that had been done by a few magazines, it has been seen that the mortise and tenon joint is the strongest and most superior to all other types of joints.

it was shown that the mortise and tenon joint could take up to 1005 lbs. of force before it breaking whereas the biscuit miter joint could hold up to only 220lbs of force and the dado did hold up to 559 lbs. of force even when it was reinforced with screws.